Metal Replacement Overview:

|

The biggest incentive for metal replacement with polymers is cost. Many people unfamiliar with structural plastics view these materials as being “cheap”. In reality, the plastic materials which are truly structural in nature actually cost more per pound than the metals that they are replacing.

|

|

Given this fact, the question, “WHY PLASTICS?” is logical and requires some exploration. In order for structural composites to compete with metals in a particular application, there must be some cost incentive in the larger picture. When high volume purchases of steel can be made for $0.26/lb, and unfinished aluminum die castings bought for $2.00/lb, when do plastics make sense? |

To “parts consolidate,” or integrate several components into a single molded part:

The elimination of labor and process costs associated with joining or assembling several components is a very important consideration in the decision to use plastics. Aside from labor and process costs, one hidden cost that many overlooks are scrap. For example, if one assembles two parts costing one dollar each and encounters a bad weld, the total value of the scrap is two dollars, PLUS the cost of the weld and inspection. Although this is a simple example, it illustrates the potential cost savings associated with parts integration, regardless of material

Howarth Development Associates can identify cost-saving applications for plastics and composites in your product line.

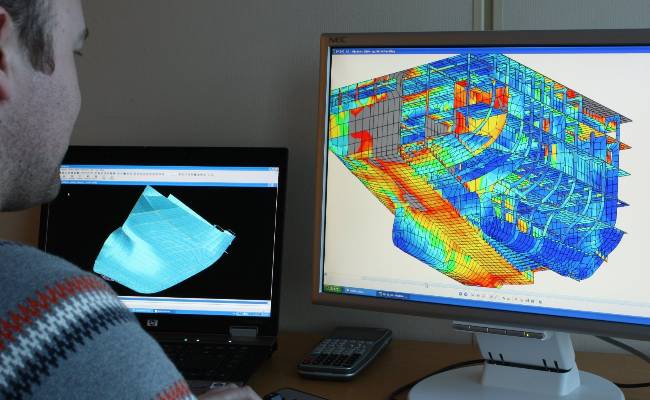

We are very experienced in metal to plastic translations, and can provide design concepts and validate structural integrity of components which provide a cost incentive to replace metals.

We keep current on all new fiber and resin developments, including carbon, glass, and aramid fibers, as well as high temperature materials.When secondary operations, such as machining, tapping, or welding are required:

Perhaps the most significant advantage to injection molded materials is the ability to form “net shape” components. This means that after the part is molded and de-gated, no other work is required to make that part functionally complete. With proper tool layout and part design, it is possible to incorporate a variety of features into the component which might need to be done as a secondary operation in other manufacturing processes.

To achieve chemical or corrosion resistance without the need for painting or coating:

This is one of the largest reasons that composite materials continue to replace metals in the automotive industry. Salt spray tests, which are required for all underhood and chassis components, are extremely demanding on steel, aluminum, and magnesium brackets, etc. To prevent corrosion of metal components, a protective coating must be added, which increases part cost.

To reduce weight, while maintaining component performance for “extreme” applications:

Composite materials are known for their high specific strength and stiffness (strength and stiffness per weight). The need to reduce weight becomes extremely important for applications of mobility where weight creates a recurring cost penalty. Commercial aircraft, for example, fly for twenty to thirty years. An aircraft which is overweight will consume more fuel and have less carrying capacity (fewer seats sold) than a more efficient design. Compounded over the life of a plane, these costs easily justify the increase in purchase price of a plane with more advanced (and more expensive) materials. Note that the extreme applications are generally performance (not cost) driven, and have a greater emphasis on performance.